Drain, Waste, and Vent (DWV) Isometric Design & Plumbing Plans – San Francisco Experts

A DWV isometric drawing maps every drain, waste, and vent connection in three dimensions—showing pipe sizes, slopes, cleanouts, trap arms, and vent terminations—so your team and inspectors can quickly verify compliance with the California Plumbing Code (CPC) and the San Francisco DBI. At Heidi’s House Construction, we turn complex remodels and ADUs into clear, permit-ready DWV plans that prevent field conflicts, failed inspections, and costly rework. From fixture-unit calculations and allowable trap-arm lengths to wet-vent/circuit-vent layouts and roof penetrations, our drawings translate real jobsite conditions into precise, buildable plumbing plans.

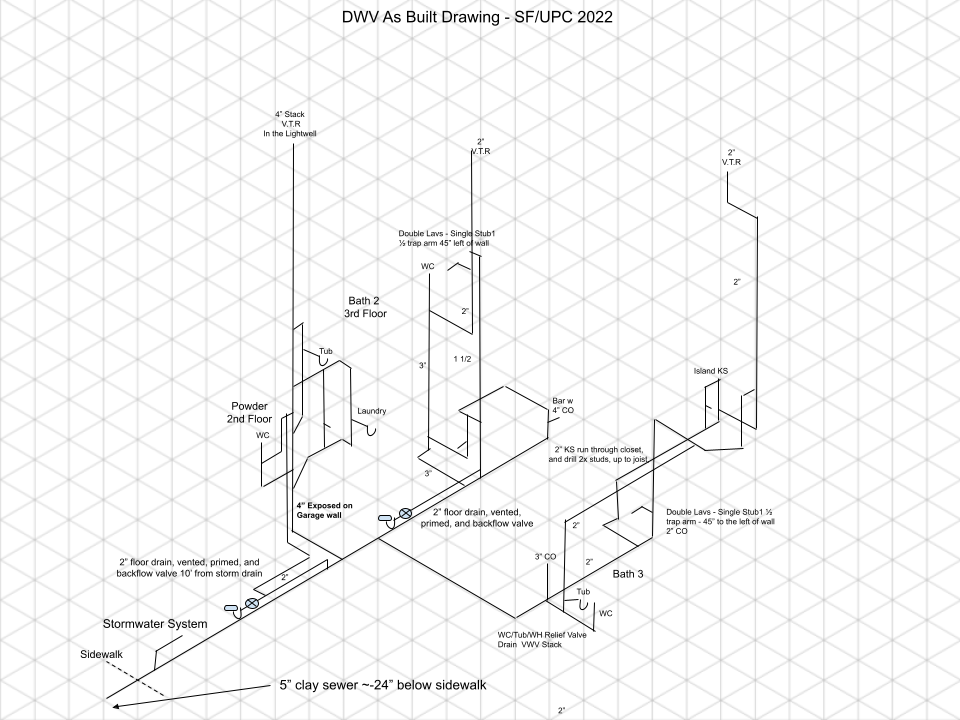

This DWV as-built drawing illustrates the complete drainage, waste, and vent layout for a multi-story residence in San Francisco. Designed in compliance with UPC 2022, it documents all vent stacks, fixture connections, cleanouts, and stormwater integration—ensuring accuracy for inspection, maintenance, and future remodel coordination.

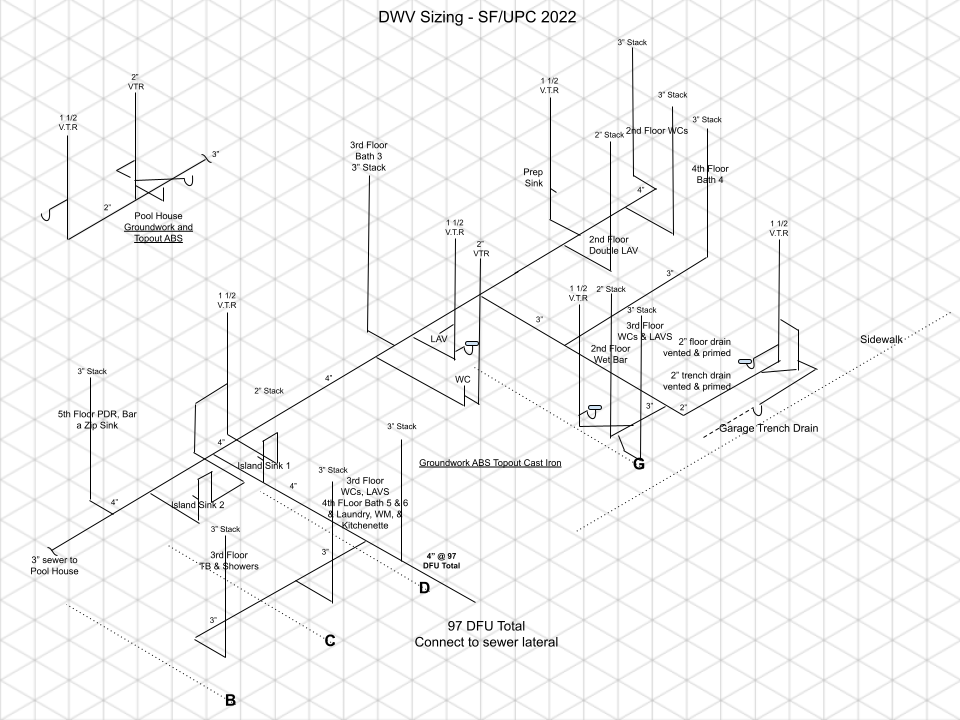

A detailed DWV sizing diagram calculating load, fixture units, and venting for a five-story San Francisco project. This schematic defines pipe diameters, drainage paths, and vent terminations per UPC 2022, achieving 97 total DFUs and full compliance with city standards for multi-unit construction.

Code-Clean DWV Plans, Built for SF Inspections

Quick inspection approvals start with an accurate isometric. Our team combines over 40 years of licensed plumbing experience with traditional isometric drafting to deliver DWV plans that secure approvals and ensure clean installations the first time. We size stacks and branches correctly, call out cleanouts and test methods, coordinate with structural and architectural plans, and document backwater valve requirements where fixtures are subject to sewer backflows—everything your reviewer expects to see.

We proudly serve San Francisco’s Richmond and Sunset Districts and North Bay communities (Novato, Corte Madera, Sausalito). Whether you’re doing a gut renovation, adding a bathroom, converting space to an ADU, or repiping an entire home, we’ll produce a clear, inspector-ready DWV isometric tailored to your project.

Frequently Asked Questions

1) What is a DWV isometric drawing, and why do you need it?

A DWV isometric is a 3D diagram showing how every fixture connects to the drain, waste, and vent system, including pipe sizes, slopes, and vent relationships. A DWV isometric prevents field conflicts, failed inspections, and costly rework.

2) Who should prepare DWV plumbing plans?

Your best outcome comes from a licensed plumbing contractor or qualified designer with field experience. Our DWV plans are produced by plumbers who install what they design, so your isometric reflects real-world constructability and local inspector expectations.

3) How fast can I get a permit-ready DWV isometric?

Most single-family projects are completed in 2–3 business days after we receive the floor plan, fixture list, and existing conditions. Larger or multi-unit projects may take longer. We also offer expedited drafting for time-sensitive submittals in San Francisco and the North Bay.

4) What information do you need to start my DWV design?

Please provide: current floor plan(s), fixture schedule and locations, any existing plumbing drawings/photos, proposed structural changes, sewer lateral location/elevation (if known), and roof/venting constraints. If needed, we’ll site-verify conditions before finalizing.

5) Can you design for special conditions (island vents, wet/circuit venting, ejector pumps, backwater valves)?

Yes. We routinely design wet-vent and circuit-vent systems, island fixture vent solutions, sewage/effluent ejector connections, and backwater valve details where required by grade. We’ll note any AHJ-specific limitations and document the approved method for DBI review.

6) Do you coordinate cleanouts and testing requirements?

Absolutely. Your plan will specify interior/exterior cleanouts, two-way cleanouts where applicable, and the approved test method (per CPC/DBI), so the inspector can see exactly how the system will be verified during the rough-in process.